Indoor air quality has become a top priority for modern commercial and industrial buildings. Occupants now expect cleaner air, better comfort, and healthier indoor environments. At the same time, buildings must manage rising energy costs and stricter efficiency standards. These competing demands have made ventilation design more complex than ever.

Treated fresh air systems offer an effective solution by delivering controlled, conditioned outdoor air into buildings. Instead of relying on uncontrolled ventilation, these systems treat incoming air to maintain comfort and efficiency. As a result, they play a key role in improving indoor air quality while reducing energy consumption.

What Is a Treated Fresh Air System?

A treated fresh air system is a specialized HVAC solution designed to supply filtered and conditioned outdoor air to indoor spaces. Unlike conventional ventilation systems, it treats fresh air before introducing it into the building. This ensures that temperature, humidity, and air cleanliness are maintained at optimal levels.

These systems are commonly integrated with central air handling units or operate as standalone units. By separating ventilation air from return air, treated fresh air systems allow precise control over indoor conditions. This makes them ideal for buildings with high occupancy or strict air quality requirements.

Why Indoor Air Quality Matters in Commercial and Industrial Buildings?

Indoor air quality directly affects occupant health, comfort, and productivity. Poor air quality can lead to discomfort, fatigue, and increased health risks. In industrial settings, inadequate air quality can also impact product quality and equipment performance.

Maintaining good indoor air quality helps reduce airborne contaminants and ensures proper oxygen levels. It also supports compliance with ventilation standards and workplace safety guidelines. For building owners, improved indoor air quality translates into better occupant satisfaction and long term operational value.

Common Ventilation Challenges in Modern Buildings

Modern buildings face several ventilation challenges due to changing usage patterns and environmental conditions. Higher occupancy levels and tighter building envelopes increase the need for effective ventilation strategies. Outdoor air conditions further complicate system design.

Common challenges include:

- Increased demand for fresh outdoor air

- High outdoor humidity and temperature variations

- Airborne pollutants and particulate matter

- Energy losses from uncontrolled ventilation

- Difficulty balancing comfort and efficiency

Treated fresh air systems are designed to address these challenges efficiently.

How Treated Fresh Air Systems Work?

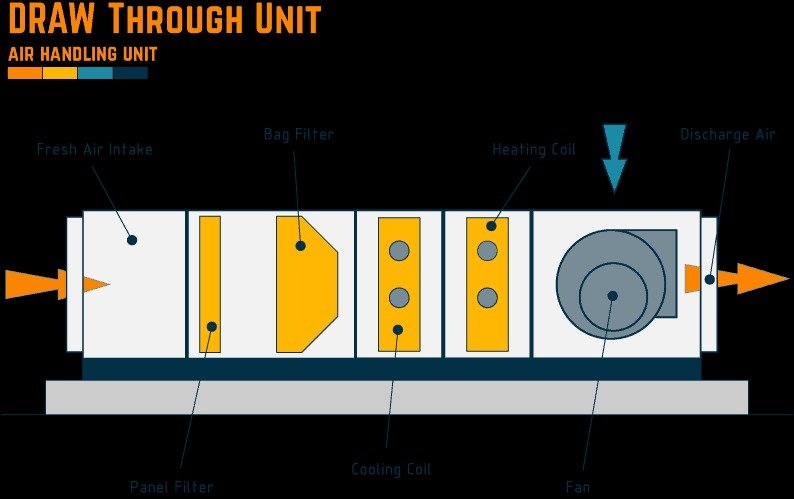

Air Intake and Filtration Process

Treated fresh air systems begin by drawing outdoor air into the unit. This air passes through multiple filtration stages to remove contaminants such as dust, pollen, and pollutants. High quality filtration improves indoor air cleanliness before air reaches occupied spaces.

The filtration process typically includes:

- Pre filters for large particles

- Fine filters for smaller contaminants

- Optional advanced filtration for specific applications

This ensures consistent delivery of clean air throughout the building.

Temperature and Humidity Control

After filtration, the air is conditioned to match indoor requirements. Temperature and humidity control are essential for occupant comfort and system efficiency. By preconditioning fresh air, the HVAC system avoids excessive heating or cooling loads.

This controlled approach helps maintain stable indoor conditions. It also reduces strain on central cooling and heating equipment, leading to improved energy performance and system longevity.

See also: TITUM Fusion Advanced Titanium Cookware Technology for Precision and Performance

Role of Treated Fresh Air Systems in Energy Efficiency

Energy efficiency is a major advantage of treated fresh air systems. By conditioning outdoor air before it enters the building, these systems reduce the workload on primary HVAC equipment. This results in lower energy consumption and improved system efficiency.

When integrated with energy recovery technologies, treated fresh air systems can reuse energy from exhaust air. This further improves overall performance and reduces operational costs. Over time, these energy savings contribute to a strong return on investment.

Key Benefits of Using Treated Fresh Air Systems

Treated fresh air systems provide multiple benefits that support both indoor air quality and energy efficiency. These advantages make them essential for modern building design.

Key benefits include:

- Improved indoor air quality and ventilation

- Consistent supply of fresh, filtered air

- Better control of temperature and humidity

- Reduced energy consumption

- Enhanced occupant comfort and productivity

These benefits support healthier and more efficient indoor environments.

Applications of Treated Fresh Air Systems

Commercial Building Applications

Commercial buildings often experience high occupancy and extended operating hours. Treated fresh air systems help maintain air quality while managing energy use.

Common commercial applications include:

- Office buildings

- Shopping malls

- Hotels and hospitality facilities

- Educational institutions

These environments benefit from consistent ventilation and comfort control.

Industrial Applications

Industrial facilities require reliable ventilation to manage heat, humidity, and airborne contaminants. Treated fresh air systems provide controlled ventilation without compromising efficiency.

Industrial applications include:

- Manufacturing facilities

- Pharmaceutical and cleanroom environments

- Warehouses and logistics centers

- Laboratories and research facilities

In these settings, treated fresh air supports process stability and worker safety.

Treated Fresh Air Systems vs Conventional Ventilation Systems

Conventional ventilation systems often introduce untreated outdoor air directly into buildings. This can lead to energy losses and inconsistent indoor conditions. Treated fresh air systems provide a more controlled and efficient approach.

Compared to traditional systems, treated fresh air units offer better humidity control, improved filtration, and reduced HVAC load. This results in lower operating costs and enhanced system performance over time.

Role of Treated Fresh Air Systems in Sustainable Building Design

Sustainable building design emphasizes energy efficiency and occupant well being. Treated fresh air systems align with these goals by reducing energy waste and improving indoor air quality. They support compliance with energy efficiency standards and green building certifications.

By optimizing ventilation performance, these systems help reduce carbon emissions associated with heating and cooling. This makes them an important component of environmentally responsible HVAC design.

Factors to Consider When Selecting a Treated Fresh Air System

Selecting the right treated fresh air system requires careful assessment of building needs and environmental conditions. Proper selection ensures optimal performance and efficiency.

Important factors include:

- Required airflow and ventilation rates

- Local climate and humidity levels

- Filtration and air quality requirements

- Integration with existing HVAC systems

- Maintenance and service accessibility

Considering these factors helps ensure long term reliability.

Maintenance and Performance Optimization

Routine maintenance is essential for keeping treated fresh air systems operating efficiently. Regular filter replacement and system inspections help maintain air quality and airflow performance.

Monitoring system performance allows facility managers to identify issues early. Proper maintenance extends equipment life and ensures consistent indoor air quality.

Future Trends in Treated Fresh Air Technology

Advancements in HVAC technology are driving improvements in treated fresh air systems. Smart controls and real time air quality monitoring are becoming more common. Integration with energy recovery and building automation systems is also increasing.

As demand for healthier buildings grows, treated fresh air systems will continue to play a central role in indoor air quality solutions.

Conclusion and Contact CTA

Treated fresh air systems are essential for improving indoor air quality while controlling energy costs in modern buildings. By delivering clean, conditioned outdoor air, these systems address ventilation challenges and support efficient HVAC operation. Their role in comfort, health, and sustainability makes them a critical component of contemporary building design.

To learn more about advanced indoor air quality and ventilation solutions, connect with Desiccant Rotors International and explore how their treated fresh air systems can enhance building performance.